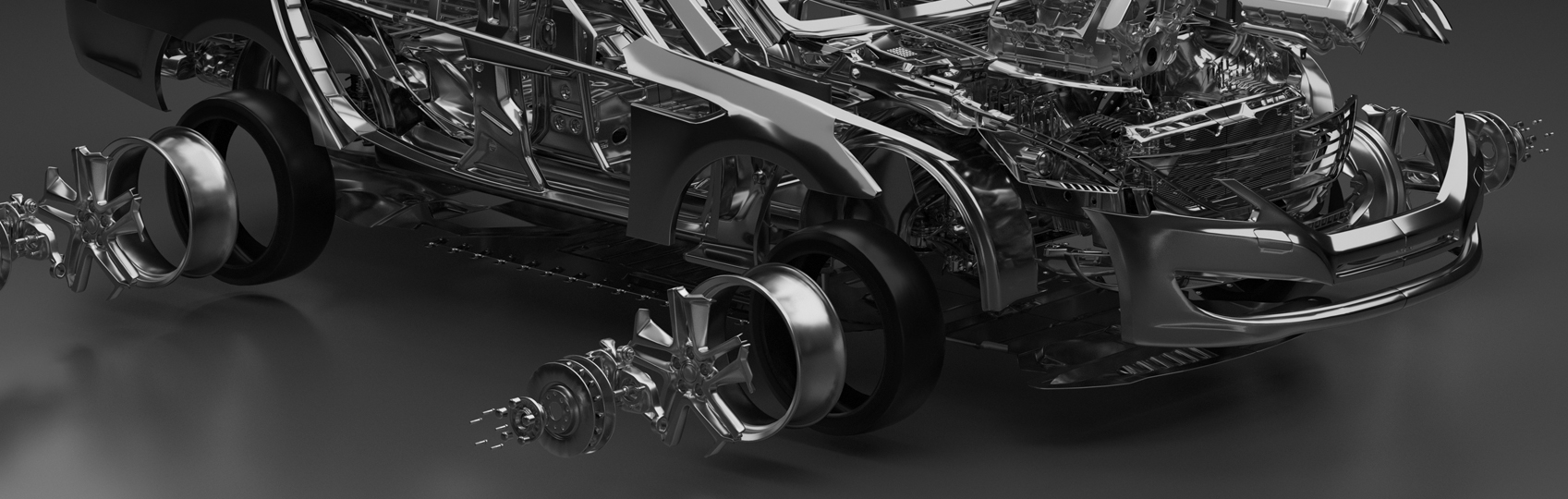

Automobile lamp mold design and manufacturing solution

Lamp is an indispensable set of accessories for cars. Whether it is a traditional or technological fashion model, the main parts of the lamp are inseparable from the headlamp body, reflector, decorative frame and light distribution mirror. As the most demanding parts of automobile appearance parts, the requirements of mold design and manufacturing process for lamp are also very high.

First of all, the challenge comes from the headlight body.

Automobile lamp body is an internal functional part. Although the appearance requirements are not high, there are many assembly holes and buckles, which means that the following risks may exist in the design and manufacture of lamp body mold:

1. There are many die inclined tops, sliders and inserts, which are easy to break and flash;

2. Complex water transportation structure / difficult cooling uniformity;

3. Large amount of discharge motor / more monomer electrodes

Secondly, for the reflector, we need to combine the particularity of product specifications to carry out mold design.

The reflector, also known as the reflector, is a part of the automobile headlamp lighting system that has the function of reflection to avoid direct light. It is an appearance part. The surface is high gloss electroplated and has a large area of texture for surface decoration. Because the reflector needs to work in a high temperature environment, it is required to be beautiful while realizing the purpose of reflection and concentration. Therefore, automobile manufacturers often choose prefabricated monolithic molding compound (BMC) thermosetting plastic with heat resistance, flame retardancy and strong creep resistance to form the reflector.

For the manufacturing requirements of reflectors with strict light distribution and direct aluminum plating, Hanyi industry suggests that attention should be paid to the following in mold design:

1. The parting surface of the mold cannot be avoided, and it is easy to have flash;

2. The intersection position and welding line shall be accurately analyzed in the early stage;

3. The heating rods of the front and rear mold are evenly and reasonably distributed to prevent deformation;

4. Jacketing is added to prevent high temperature burning;

5. The surface texture contour requires high accuracy;

6. As far as possible, the mold kernel is not easy to be disassembled as a whole to avoid internal criticism of the product.

Thirdly, for the lamp decorative frame, we should pay attention to the realization of its high surface requirements to do the mold design.

The lamp decorative frame is a decorative part of the automobile headlamp lighting system. It is located inside the lens and assembled with the lens. People can see the decorative frame from the outside of the lamp through the lens. Generally, the manufacturing materials of lamp decorative frame are PC, pbt+gf, pbt+pet, pa+gf, and the surface is required to be electroplated.

Therefore, the experience of Hanyi industry is to select high-quality mold materials and pay attention to:

1. The intersection position and welding line should be analyzed accurately in the early stage;

2. The front mold should be smooth and prevent sticking to the front mold;

3. Water transportation and ejection design to prevent deformation;

4. Pay attention to the texture depth to prevent flow printing

Finally, the lens also needs high-quality mold design and mold manufacturing to complete the product molding.

Lens, also known as lens, is the outermost transparent part of car headlights. Generally, the headlights of cars are white and transparent, and the rear combination lamps are red (or multicolor) and transparent. The surface of the lens is A-level surface (that is, the gap between adjacent surfaces is between 0.001 and 0.005mm, the curvature changes below 0.005 degrees, and the tangent changes below 0.16 degrees.), The outer surface has superhard coating, and the transparency of the inner and outer surfaces is highly required.

Key points of mold:

1. The intersection position and welding line shall be accurately analyzed in the early stage;

2. There is line print control of internal drawing line, inclined top line and thimble line;

3. The design of two-color / three color and multi-color parting sealing surface is very important;

4. Pay attention to the texture depth to prevent flow printing;

5. The exhaust design should be sufficient, reasonable and effective;

Based on the above product requirements and mold characteristics, immetech has perfect solutions from raw materials to mold delivery:

1. All materials are selected from professional automobile mold steel manufacturers such as Germany smobagen / Japan Datong / Sweden yishengbai;

2. Machining adopts high-precision high-end imported equipment: DMG (CNC) and Fanuc (CNC) /mitsubishi mirror and Makino (EDM) / Sodick (WEDM) /erowa processing system

3. Selection of standard parts: the mold embryo is dme/hasco/futaba/lkm; 2. The hot runner is synventive/incoe/moldmasters/yudo; 3. The oil cylinder is parker/smc/heb/merkle/hps

4. Professional and scientific inspection methods are used in every link from design to mold delivery: design is verified by professional UG design software and Moldflow verification software / steel is verified by ht110 hardness tester / machining is verified by hexcon three-dimensional measurement system / surface is verified by jd520 surface roughness instrument / assembly is verified by shunxin200t flying mold machine / product molding feasibility is verified by 1920t three-color injection molding machine

Immetech has never stopped demanding high-precision products and molds in both hardware and software. Just like the mission of immetech: aspire to become a benchmark enterprise for the spirit of new craftsmen in the industry!

Automobile lamp mold design and manufacturing solution